Polypropylene (PP) Pleated Filter Cartridges

Product Line Description

PP Pleated Filter Cartridge cater to high efficiency filtration requirement. They are constructed of high purity polypropylene materials which increasing dirt holding capacity. The materials comply with FDA related requirement. The high surface area enable high flow rates and long service life. The series of cartridge with multiple layered microporous ensure stable performance and broad chemical compatibility. The micron rating can be nominal and absolute.

| Specifications | |

|---|---|

| Brands | JMCC |

| Material of Construction | |

| Filter Media | Polypropylene (PP) |

| Support | Polypropylene (PP) |

| Core/Cage/End Adapter | Polypropylene (PP) |

| Sealing Method | Thermal Bonding |

| Filtration Area Per 10 Inch (in) Length | 0.61 m² |

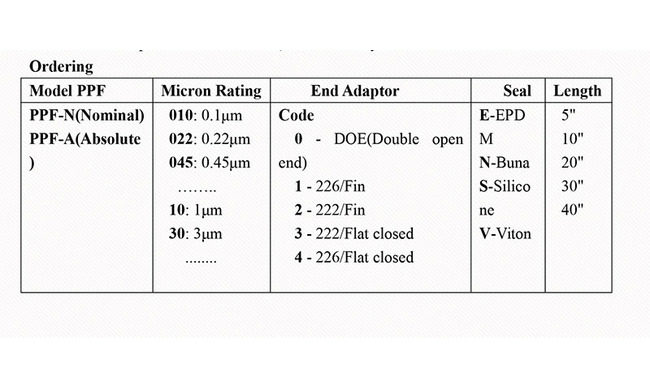

| Ordering Information | |

| Model | PPF-A – Absolute PPF-N – Nominal |

| Micron Rating | 010 – 0.1 µm 022 – 0.22 µm 045 – 0.45 µm 10 – 1 µm 30 – 3 µm |

| End Adapter | 0 – DOE (Double Open End) 1 – 226/Fin 2 – 222/Fin 3 – 222/Flat Closed 4 – 226/Flat Closed |

| Seal Materials | E – Ethylene Propylene Diene Monomer (EPDM) N – Buna S – Silicone V – Fluorocarbon (FKM) |

| Dimensions | |

| Length | 5 – 5 in. 10 – 10 in. 20 – 20 in. 30 – 30 in. 40 – 40 in. |

| Outside Diameter | 2.7 in 69 mm |

| Recommended Operating Conditions | |

| Forward Pressure at 23 Degree Celsius (ºC) Temperature | 4.2 bar |

| Forward Pressure at 80 Degree Celsius (ºC) Temperature | 1 bar |

| Maximum Operating Temperature | 80 ºC |

| Sterilization Temperature | 120 ºC |

| Sterilization Time Per Cycle | 20 min |

| Number of Sterilization Cycles | 5 |

| Applications | |

|

|