Polypropylene (PP) Melt Blown Filter Cartridges

Product Line Description

PP Melt Blown Filter Cartridge is constructed of pp without any chemical glues. The structure is loose outside and close inner. As the depth fiber and density make the filter cartridge in strong pollutants holding capacity. It can remove contaminant effectively. It can be make by 3 layers or 6 layers which conform with FDA standard requirement.

| Specifications | |

|---|---|

| Brands | JMCC |

| Ordering Information | |

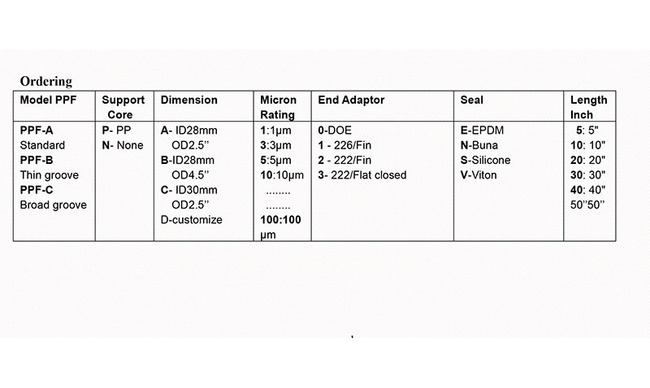

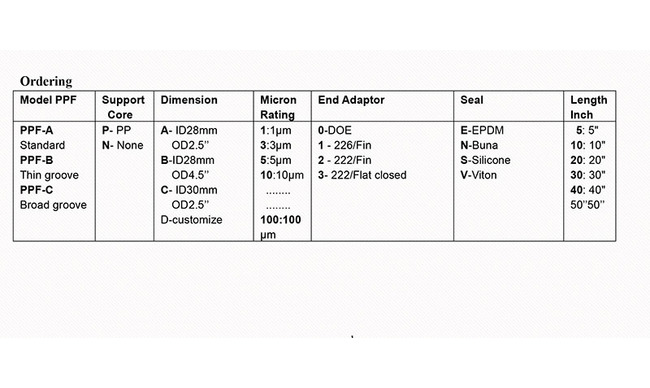

| Model | PPF-A – Standard PPF-B – Thin Groove PPF-C – Broad Groove |

| Support Core | N – None P – Polypropylene (PP) |

| Dimension | A – 28 mm Inside Diameter/2.5 in. Outside Diameter B – 28 mm Inside Diameter/4.5 in. Outside Diameter C – 30 mm Inside Diameter/2.5 in. Outside Diameter D – Customize |

| Micron Rating | 1 – 1 µm 3 – 3 µm 5 – 5 µm 10 – 10 µm 25 – 25 µm 50 – 50 µm 100 – 100 µm |

| End Adapter | 0 – DOE (Double Open End) 1 – 226/Fin 2 – 222/Fin 3 – 222/Flat Closed |

| Seal Materials | E – Ethylene Propylene Diene Monomer (EPDM) N – Buna S – Silicone V – Fluorocarbon (FKM) |

| Length | 5 – 5 in. 10 – 10 in. 20 – 20 in. 30 – 30 in. 40 – 40 in. 50 – 50 in. |

| Recommended Operating Conditions | |

| Maximum Operating Temperature | 80 ºC |

| Maximum Differential Pressure at 21 Degree Celsius (ºC) Temperature | 2.0 bar |

| Applications | |

|

|