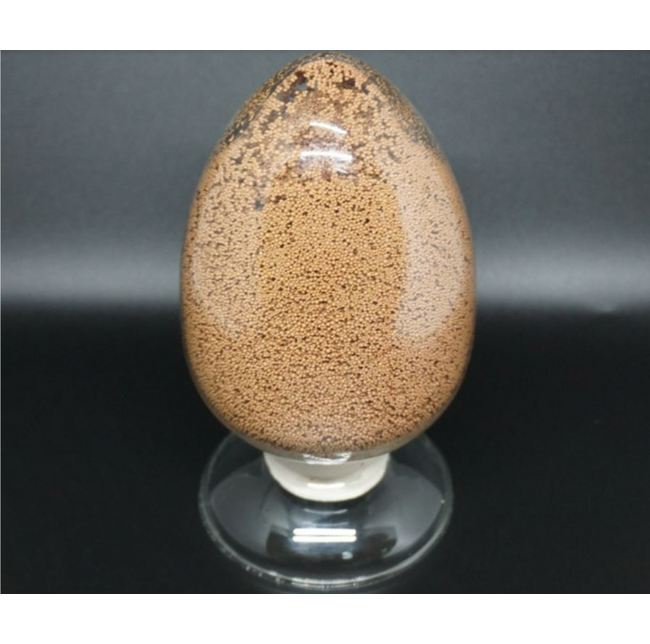

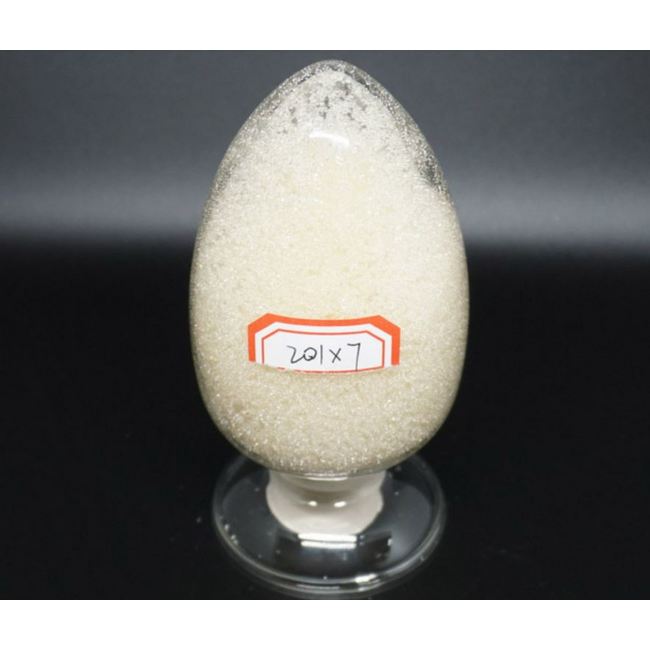

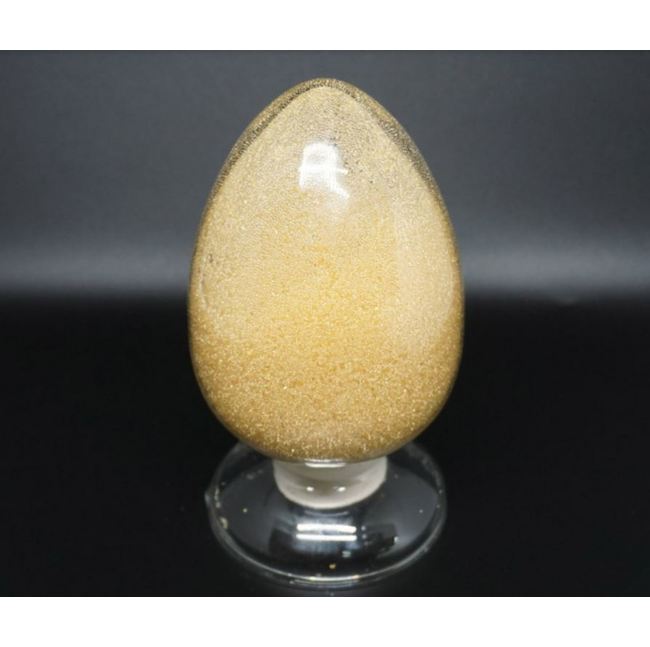

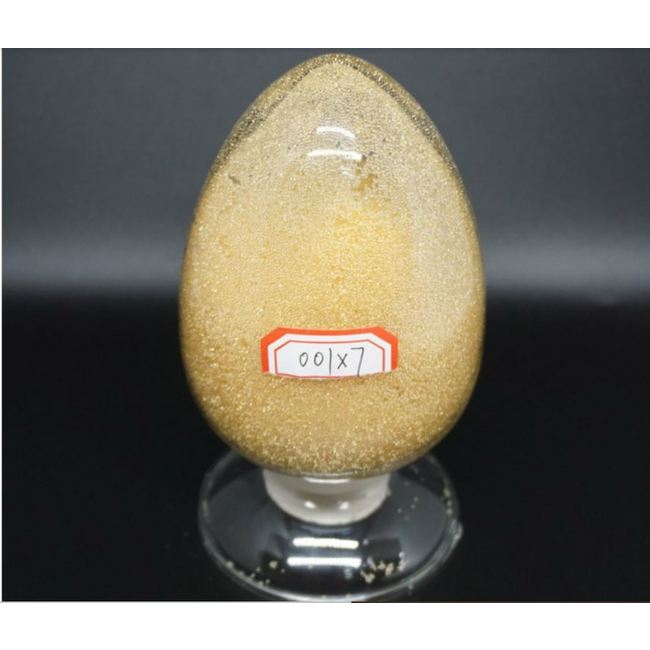

201×4 Strong-Base Type I (Gel) Anion Exchange Resins

Product Line Description

201×4 (711) is a high capacity, shock resistant, gelular, Type I, strongly basic anion exchange resin supplied in the chloride or hydroxide form as moist, tough, uniform, spherical beads. 201×4 (711) is intended for use in all type of deionization systems and chemical processing applications and is especially suited for use in regenerable mixed beds. It also shows good kinetics of exchange, enabling very low concentration levels of both strong and weak acid anions to be achieved at practical flowrates.It is mainly used in pure water and high purity water manufacturing, sugar solution decolorization, wastewater treatment, extraction of biochemical products and radioelements etc.

| Specifications | |

|---|---|

| Brands | HUAMO JMCC |

| Typical Physical and Chemical Properties | |

| Polymer Matrix Structure | Crosslinked Polystyrene Divinylbenzene |

| Physical Form and Appearance | Spherical Beads |

| Functional Groups | -N(CH3)3OH |

| Ionic Form (As Shipped) | CL– |

| Chlorine (CL–) Form, Wet, Volumetric Total Capacity | ≥ 1.3 eq/l min |

| Chlorine (CL–) Form Moisture Retention | 48 to 58 % |

| Particle Size Range | 0.3 to 1.2 mm |

| Maximum Percentage (%) for < 0.3 Millimeter (mm) Particle Size | 1 % |

| Maximum Uniformity Coefficient | 1.6 |

| Effective Size | 0.4 to 0.7 mm |

| Maximum Reversible Swelling Chlorine (CL–) → Hydroxide (OH–) | 20 to 30 % |

| Approximate Shipping Weight | 660 to 720 g/L |

| Moist Chlorine (CL–) Form Specific Gravity | 1.08 |

| Potential of Hydrogen (pH) Stability Range | 0 to 14 pH |

| Suggested Operating Condition | |

| Hydroxide (OH–) Form Maximum Temperature | 60 ºC 140 ºF |

| Chlorine (CL–) Form Maximum Temperature | 80 ºC 176 ºF |

| Backwash Rate (Bed Expansion) | 50 to 75 % |

| Regenerant Concentration (Sodium Hydroxide (NaOH)) | 2 to 4 % |

| Regenerant Dosage (Sodium Hydroxide (NaOH)) | Sodium Hydroxide (NaOH) Volume:Resin Volume = 3:1 |

| Regenerant Flow Rate | 2 to 4 BV/h |

| Regenerant Contact Time | At Least 40 min |

| Service Flow Rate | 10 to 25 mph |